A Place of My Own (31 page)

Authors: Michael Pollan

The resolution of the images on the CD-ROM was too poor for me to discern whether any given window opened in or out, but it allowed me to narrow my search to a series of houses with promising-looking casements. The librarian pulled my selections from the file drawers, spreading the delicate buff pencil drawings on a table while reciting the archive’s rules: no photocopying, no tracing, no ballpoint pens or ink markers on the table. Great. The last best hope for my windows, if not for the integrity of my building’s design, rested on my skill as a freehand draftsman, which was exactly nil.

I washed my hands and started going through the drawings. Most of the houses pictured were elaborately timbered bungalows with a great many shallow gables piled one on top of the other in a manner reminiscent of Japanese architecture. You could see why a cabinetmaker who called his business the Craftsman Woodshops would respond to this work: the Greenes’ designs owed a lot to the Arts and Crafts movement, sharing its emphasis on traditional craftsmanship in wood. With their exposed structures and hand-worked finishes, many of the houses look like celebrations of the very possibilities of wood and the art of joinery; they exhibited in their design and finishes a kind of transparency to the craftsmanship that made them. Coming at a time when such craftsmanship was under attack from the factory system, such an aesthetic had a strong moral cast, made a last-gasp protest against the machine age and an assertion of the dignity of work. It is a message that still seems to speak to many carpenters today (and not only to them).

By the end of the morning, I had found what I was looking for: an ingenious construction detail for an in-swinging casement window on a house in Pasadena. I kept going, and began to find variations on the same idea over and over again, in one house after another. The window must have worked, I reasoned, or else the Greenes would have tried some radically different tack or given up on the in-swing altogether. So I copied the window detail into my notebook as carefully as I could, checking it once and then again to make sure I’d left nothing important out (assuming of course that I knew what important looked like).

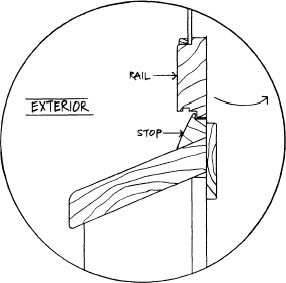

To my inexpert eye it seemed a fine solution, economical in the best sense. The bottom frame of the sash, or rail, doubled as a drip edge; by designing the rail to overhang the stop, the designer ensured that any water coming down along its face would fall onto the sill rather than the stop. And the curved profile of the stop itself eliminated any surface on which water might linger. At first I didn’t understand the purpose of the groove routed into the underside of the sash, but when I brought the drawing to Jim the following Saturday, he grasped its significance immediately.

“Capillary action. Water wants to migrate along the underside of a surface, so it’ll work its way back to that gap there unless something is put in its way. That’s what the groove’s for: Water will collect in it until the bead gets heavy enough to break the surface tension. Then it’ll drop onto the sloping side of that stop and down to the sill and away.” Here was a case of thinking like water at the Ph.D. level.

Jim felt the detail was definitely workable, though he’d need to adapt it some. For one thing, Connecticut gets a lot more rainfall than California does; for another, my windows would be made of painted pine rather than unfinished redwood (far too heavy for sash this size, never mind the expense), and he worried about the ability of such a slender pine stop to withstand the weight of sash banging against it. But he had some ideas. Jim gave me his price, which seemed fair in view of the complexities. It was, however, somewhat more than I could afford. Jim suggested I could shave several hundred dollars off of the total if I was willing to make the four little peak windows myself, a job he assured me was fairly straightforward. So we pulled these items out of the deal and shook hands on it.

Jim had said it would be okay with him if I wanted to watch him build the windows, so early on a Monday morning I came by his shop. On a pallet by the front door stood a short stack of fresh, rough-sawn white pine planks of various lengths, knot-free and covered in a soft blond down. Nothing about this wood made you think “window”; it could not have been more opaque or inert. And yet what Jim proposed to do before the morning was over was transform this stack of lumber into intricate skeletons of finished white pine, the airy frames of six divided-light windows. The singleness of “stock”—what Jim called the raw pine—would be translated into that rich, antique, and multifarious vocabulary English offers for the parts of a window: sashes and stiles, muntins and mullions, sills and jambs and rails and casings and lights.

Jim’s shop consisted of two large rooms divided by wooden racks stacked with handsome slabs of unfinished oak, cherry, mahogany, maple, and pine. Both spaces were crowded with doors, windows, cabinets, and countertops arrested in various stages of fabrication, and the whole place looked as though a blizzard had recently passed through, coating everything in several inches of fresh, fragrant sawdust, Jim included. The back room held two large, low tables where Jim did his layouts and glue-ups. Up front were a half-dozen machine tools spread out around the room in a rough approximation of an assembly line, separate stations each for the planer, shaper, table saw, tenoner, mortiser, and drill punch. It seemed like an awful lot of machinery for a woodworker as devoted to tradition as Jim professed to be.

“They’ve improved on the chisel some,” Jim said as he set to work, bunching the sleeves of his sweatshirt at the elbows, “but the mortise joint is still the best we know how to make.” In this Jim’s thinking was in keeping with the Arts and Crafts movement for which he obviously felt a kinship. Gustav Stickley, the turn-of-the-century furniture maker who promoted Arts and Crafts ideas in America, had objected not to the machine as such but to the uses to which it was being put, including mass production and the devaluing of craftsmanship. “When rightly used,” Stickley had written in

The Craftsman

, the influential magazine he began publishing in 1900, “the machine is simply a tool in the hand of a skilled worker.”

In Jim’s hands, the machine was a howling and slightly terrifying agent of transformation. Working with a swiftness that went some distance toward explaining the condition of his fingers, Jim escorted each rough plank from one station to the next, guiding the pine along on a journey of ever-increasing refinement and specificity. First he would select a piece of stock from the pile by the door and feed it through the planer, a steel sandwich of spinning blades that peeled a thin, even layer from both sides of the wood at once, leaving it smooth and plumb. Now Jim would lay the piece down against a full-scale diagram of the window he’d drawn on a masonite board, decide on its role (muntin, stile, rail, etc.) then mark it for width and length and cut it on the table saw. Next the stock would enter the snout of the shaper, from which it emerged looking like a piece of finished molding, its square corners having acquired the curved profile of a coping or fillet, ogee or reverse ogee, depending on the bit used. Shouting over the scream of the machine, Jim said that shaper bits cost upward of a thousand dollars apiece, so it was tough luck if I didn’t like the one he owned. My windows received the same austere profile you see all over New England, their crossbars, or muntins, narrowing down from glass pane to nosing in three quick curving steps, each about half the size of the one preceding. Not too finicky, but not too plain either; I liked it fine.

From here on, the destiny of the various pieces of stock diverged, as some were designated tenons and others mortises, male or female depending on how they would ultimately fit into the window frame. The muntin bars that would hold the panes of glass in place would all be tenoned into the stiles and rails for maximum strength; each muntin passed through a tenoning machine that whittled its ends down to a narrow rectangular tongue of wood. The beefier members that would receive the muntin bars went instead to the mortiser, a modified drill press that cut perfectly matched notches using a spinning bit in combination with a chisel. Every one of these machines looked and sounded hungry for fingertips.

Once all the pieces had been cut and shaped, Jim spread them out on his worktable and began fitting them together, like a puzzle. With a gentle tap of his wooden mallet, the tenons snapped smartly into their notches, the molding designs neatly turning the corners and matching up, concave fillets meeting fillets, convex copings meeting copings. The machine tolerances were so exact that, except for the largest sash, whole frames virtually squared themselves. Satisfied with the fit, Jim would take the frames apart, spread glue over tenons and into notches, and then reassemble them. After checking for square, he’d clamp the frames end to end and put them aside to dry. In a day or two, he’d send the frames out to the man who did his glazing. “There’s a knack to working the putty just right,” he explained when I asked why he subbed out this particular step. “Glazing’s an old-timer’s game.”

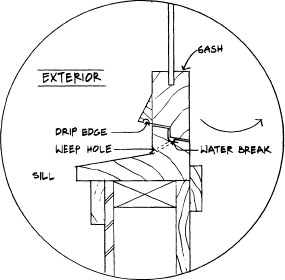

Once the frames were assembled, I studied Jim’s drip edge detail. It looked like this:

It was ingenious, if not quite as economical as the Greene and Greene detail on which it was based. Like theirs, the bottom edge of my sash extended well out over the stop, in order to conduct water away from the window, and it had a groove routed along its underside to thwart any capillary action. But below, the design diverged from its model, since Jim had decided he couldn’t taper the stop, as the Greenes had done, to minimize its surface area. Pine wouldn’t have been strong enough, for one thing. But the more serious problem, and the one I never saw coming, was that in an awning window (as opposed to a casement like the Greenes’), when the projecting drip edge swung inward, it would follow a slight downward arc that would actually collide with any stop that wasn’t either set well beneath it or angled the

wrong

way—that is, toward the building’s interior, rather than away. (You had to think like wood as well as water in this business.) Jim’s solution was inspired: He angled the stop toward the building so that the drip edge would clear it coming in. Then he routed a second groove along its surface to collect any water seeping under the sash, which would then flow out through a series of weep holes drilled through the stop. Basically, Jim had provided a second line of defense.

I congratulated him on the design, a critical detail of my building that no one except perhaps another carpenter would probably ever notice. Jim was unexpectedly cranky about it. “I’m not going to start complaining yet, but I’ve got two extra days in this job already, just thinking. Architects get a lot of money to come up with this kind of detail.” Maybe, but it seemed to me that this is precisely the place where, nowadays at least, architecture stops, where it comes down either to finding a craftsman like Jim Evangelisti or a bucket.

Except for the tapping of the wooden mallet, the final assembly was mercifully quiet, and Jim talked a little about the path that had brought him to the Craftsman Woodshops, which turned out not to be so far from where he started. Jim’s family had owned the lumberyard across the street, so he’d always been around wood and carpenters as a kid, but it wasn’t until he went away to college, in Vermont, that he got serious about woodworking. One of his professors at Godard was building an authentic timber frame house, cutting his own wood off the site, milling it by hand, and framing the structure solely with hand tools—no electricity allowed. It was the seventies, remember, and Vermont was teeming with back-to-the-land types who (not unlike members of the Arts and Crafts movement) made a moral and political virtue of traditional craftsmanship and self-reliance.

After college Jim moved out to California, where he heard about the restoration of a Greene and Greene house in Berkeley. “I saw right away that the architect in charge didn’t have a clue,” Jim said. “I mean, he was

butt

-jointing everything for chrissake! Didn’t know the first thing about the joinery in that house. I practically had to force them to let me work on it.” As I listened to Jim describe the months he spent on the job—replacing a porch railing and restoring an ornate footbridge that he still had a dog-eared drawing of—I could see that the job had been a high point for him, and a formative experience. He’d found his calling. That, and his lifelong bête noire: the well-paid and ignorant architects he always seemed to end up bailing out.