The Naked Pint (46 page)

Authors: Christina Perozzi

It is now legal to brew beer at home (except in Alabama—what’s up with that?), as long as you are 21 and don’t brew more than 100 gallons a year. It is illegal to sell your homebrew, so don’t go setting up shop unless you want to go through the official procedures it takes to become a legal brewery.

Brewing is the logical next step for you, the beer lover. Nothing will bring you closer to beer than becoming its creator. You will understand the ingredients and flavor profiles in a profoundly new way once you’re following brewing recipes and adding your own imagination to the pot. For many beer connoisseurs, this is the most rewarding part of the Beer Journey: being able to concoct a beer and share their homebrew with friends and family. And this will make you even more comfortable in conversations with brewmasters on brewery visits and in quality brewpubs. But don’t worry, brewing isn’t as complicated as it may seem.

If you break down the basics of homebrew—boiling, cooling, mixing, and storing—it’s basically cooking. It is done in a pot, uses ingredients, and is served to guests. The only difference, of course, is that it is alcohol (bonus!). Though it may seem overwhelming the first time you look at a homebrew recipe and get ready to brew, don’t fret. Remember the days when you would look at a food recipe and fear the seven steps and different measurements? You eventually found that it was easier to do than it looked. It’s the same with homebrewing; daunting at first, but with practice it does get easier and more fun. And at the end of it, you have beer!

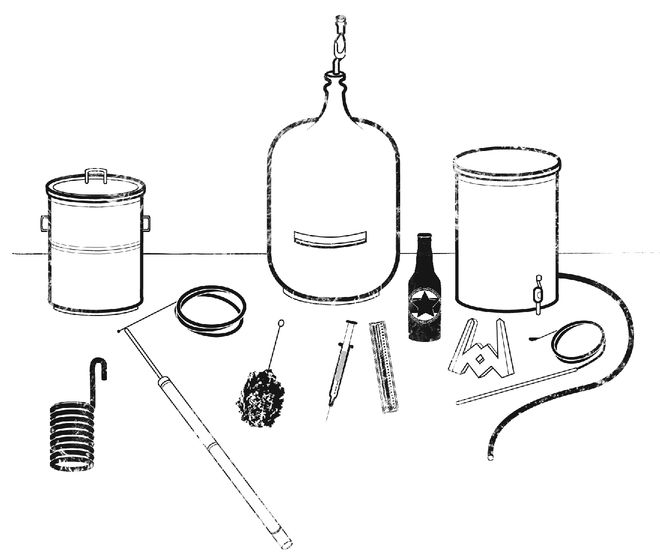

So, first things first, you need to have a homebrew equipment kit. As with any kit, you can buy the necessities separately or conveniently prepackaged together, depending on your preference. A basic homebrew equipment kit will cost you anywhere from $70 to $200, depending on how geared up you want to be. We paid about $120 for our equipment. Once you have made this initial investment, homebrew gets a lot more economical. Ingredients will cost you on average about $30 per five gallons of beer. That ends up being about 60¢ for a 12-ounce bottle, a damn good deal.

The next section is a list of things you will need to have to get to brewin’.

Tools

BREWPOT :

BREWPOT :Yes, it looks like a silver pot with a lid. But it needs to be big, at least 20 quarts, and stainless steel is best. This is where you’ll cook the malt and add some hops and, well, make the beer.

BUCKET :

BUCKET :You’ve seen these: a big cylindrical plastic thing, which often has a handle. You’ll need a large vessel, seven to eight gallons, with a good, secure, tight lid. The lid does need to have a hole in it that fits an airlock perfectly. This will be your primary fermenter, the vessel in which you will put the yeast and let your beer begin the fermentation process. The plastic needs to be food-grade, so double-check the quality of the bucket. Alternatively, you can use a glass carboy—a big glass thing that looks like those vessels people put in the watercoolers at the office. You’d need one that holds about five gallons. Unlike the plastic bucket, the carboy allows you to see the fermentation happening, and the glass seems nicer than the plastic. Note, though, that the carboy is harder to clean and easier to break.

Clockwise from left: brewpot, glass carboy with fermentation airlock and stopper, bottling bucket and hose, bottling cane and hose, capper, beer bottle, thermometer, yeast, bottle brush, siphoning cane and hose, and wort chiller.

FERMENTATION AIRLOCK AND STOPPER:

FERMENTATION AIRLOCK AND STOPPER:This is a plastic device that is wedged into the top of the fermentation vessel (your bucket lid or carboy opening) and allows for CO

2

to release during fermentation but prevents outside air from entering, which could spoil the beer.

STRAINING BAG:

STRAINING BAG:This is similar to a teabag or cheesecloth. You can use this to strain the mash. You will scoop all of the mash from the boil into this bag and then squeeze out as much liquid as possible. You don’t want to lose any of the sugar from the malt, so the squeezing is necessary. This can also be used to strain out hops at different increments during the brewing process.

WORT CHILLER :

WORT CHILLER :This is a device used to cool down the wort, enough so that you can add the yeast. If the wort is too hot, the yeast will die or act weird, and there will be no good beer (sad face).

SIPHON CANE AND HOSE :

SIPHON CANE AND HOSE :This is the vehicle the newly made beer will travel through to get to a secondary fermenter. Be sure you use food-grade plastic.

BOTTLE FILLER :

BOTTLE FILLER :This device looks like a little wand with a ball valve at the end that allows you to stop the flow of beer to keep the beer from overflowing your bottles.

EMPTY BEER BOTTLES AND CAPS:

EMPTY BEER BOTTLES AND CAPS:Remember when we told you to hold on to your empty bottles? This is why: You are probably going to want to bottle your beer. This is where your beer will undergo a secondary fermentation. Most homebrewers save bottles and then sterilize them. If you are making a five-gallon batch of beer, you will end up with 40 to 50 bottles. You can keg your beer, but beginners usually start off bottling, which makes it easier to keep and transport, and give as gifts to your lucky friends. Unfortunately bottle caps cannot be reused, but you can buy them along with new beer bottles (if you didn’t save yours) at a local homebrew supply store.

BOTTLE BRUSH :

BOTTLE BRUSH :A long brush used to make sure the bottles are clean and properly sanitized.

BOTTLIN GBUCKET :

BOTTLIN GBUCKET :After primary fermentation, you will transfer your beer into this bucket, which has a spigot on the bottom, and then transfer the beer into bottles.

Other books

Holding Their Own: A Story of Survival by Joe Nobody

Dire Desires: A Novel of the Eternal Wolf Clan by Tyler, Stephanie

9111 Sharp Road by Eric R. Johnston

The Killer Inside by Lindsay Ashford

The Infiltrators by Daniel Lawlis

Ostrich: A Novel by Matt Greene

Atrophy by Jess Anastasi

Joan of Arc by Mary Gordon

BLACKDOWN (a thriller and murder mystery) by D. M. Mitchell

Vampires Are Forever by Lynsay Sands