Why Is Milk White? (7 page)

Read Why Is Milk White? Online

Authors: Alexa Coelho

Many perfumes are made of

essential oils.

Here the word

essential

does not mean that you can't do without it but instead refers to the fact that the oil was extracted from a flower, fruit, or some other thing as an essence. This is often done by heating the material until it boils and then collecting and condensing the vapors (distilling). Other methods are solvent extraction, where the material is crushed in a solvent such as alcohol to dissolve the oils, and chromatography, where the oils wick up in a substance and separate out according to how fast they travel.

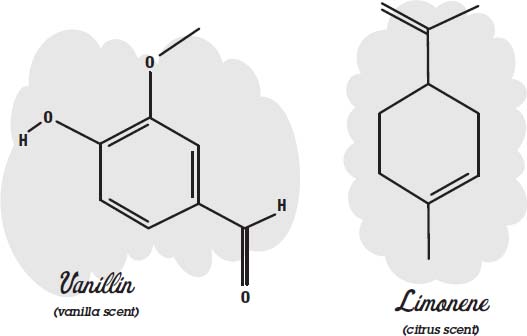

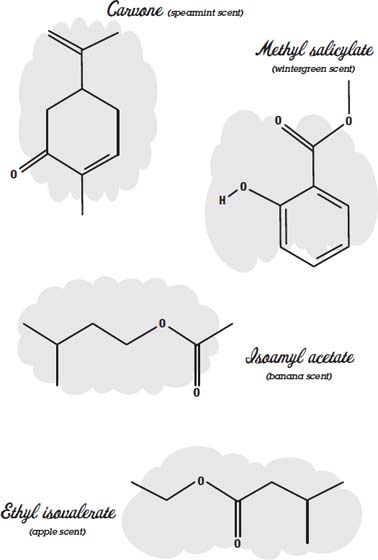

There may be 300 different compounds in an essential oil. Usually the compounds include one or more molecules that give it its characteristic odor. These molecules can be used by themselves instead of the essential oil to reduce cost or ensure reproducibility and stability in the final product.

Some examples of molecules that have characteristic scents are shown below.

Glassware is used a lot in chemistry. It is transparent, so you can watch the reactions happen. It is fairly easy to clean. It resists heating, so you can hold it over a flame to speed up a reaction or distill off a solvent. And it is fairly inexpensive.

Glass is usually made from silica (silicon dioxide, what you probably know as sand or quartz), with some sodium oxide and calcium oxide added, along with some other minor ingredients. This kind of glass is called soda-lime glass and is easy to melt and cheap.

Chemists often use borosilicate glass, which is mostly silica with some sodium oxide, aluminum oxide, and boric oxide. It resists heat shock (when something breaks if you heat it), and so it is used for heating things. Another type of glass that is good for this is fused silica, which is just pure quartz, heated to very high temperatures until it melts and can be formed. It is expensive because of the high heat required to make it.

Glass can be colored by adding other compounds, such as metal oxides. Nickel oxide makes yellows and purples, cobalt oxide gives a rich blue, and gold and copper make reds.

Lead glass is like soda-lime glass, but lead oxide is substituted for the calcium oxide and some of the silica. Since lead is so heavy, the resulting glass might be one-quarter lead by weight. Adding the lead oxide makes the glass bend light more than other glasses do, which adds sparkle to cut glass and chandelier ornaments. It is sometimes called lead crystal because of the cut shapes, but glass is not a crystalâthe molecules in any glass are all in random order, like they are in a liquid.

That disordered state is characteristic of glasses. Silica by itself would tend to crystallize, like a quartz crystal. Adding sodium oxide and calcium or magnesium oxide makes the molecules much more complex, forming networks that are too disordered to crystallize.

SILICON BOUNCY BALL

Adult

supervision

required

Materials

2 tablespoons sodium silicate solution (available at drugstores)

1 tablespoon rubbing alcohol

Disposable cup

Wooden craft stick or disposable plastic spoon

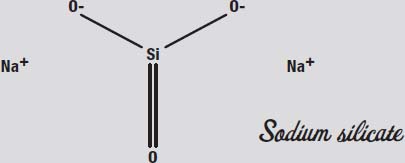

Warm, running water

Sodium silicate, also known as water glass or egg keep, is made by reacting quartz with molten sodium carbonate. That is not exactly an easy or safe thing to do at home, however. Another way to make it is to add silica gel (the sandy stuff in those little packets that keep shoe boxes and other packages dry) to a hot solution of lye (sodium hydroxide in water). This is also not exactly a safe thing to play with at home. So it is a good thing that sodium silicate solution is sold in drugstores (although usually behind the counter where you have to ask for it), because sodium silicate is fun to play with.

Sodium silicate got the name

egg keep

from the practice of coating eggs with it to preserve them before refrigeration was common. It seals the pores in the egg's shell so that no oxygen can get in. It is also a fireproofing treatment for wood, paper, and cloth for the same reason: oxygen can't get to the flammable materials.

Those little packets of silica gel mentioned earlier? They are made from sodium silicate. Manufacturers add a little acid,

such as hydrochloric acid or even vinegar, to the water glass to make a firm gel. When they dry that gel out in an oven, the water is driven off, and what remains is a delicate network of silicate crystal that has an amazingly large surface area (800 square meters per gram). At the same time the surface attracts water from the air. The result is a very good material to put in packages to protect parts from moist air.

You may have seen “magic garden” kits in toy stores or gift shops. You drop little rocks into a special solution, and the rocks slowly grow into colorful stalagmites that look like little rock trees. The solution they grow in is sodium silicate. The little rocks are made from colorful salts of metals such as copper, cobalt, and manganese.

The bits of copper sulfate or cobalt chloride dissolve and start to react with the sodium silicate, forming insoluble silicate shells around the soluble sulfates or chlorides. But the silicate shells still allow water to get to the crystals inside, and the result is cracks caused by the expansion. The salt solution squirts out, and a new insoluble silicate layer forms around it. This process repeats, forming towers and branches, each with the color of the original salt.

In this project, you are going to use sodium silicate to make a super bouncy ball.

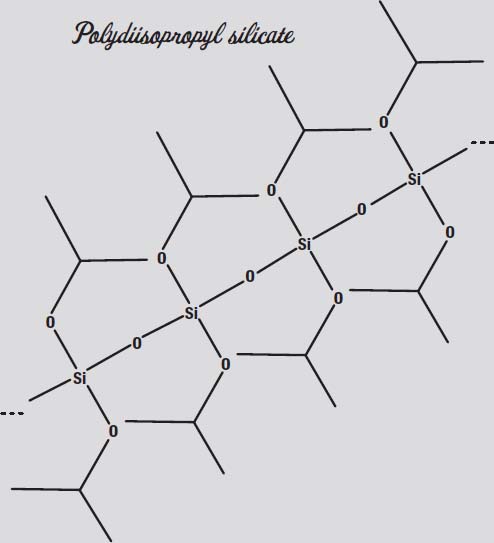

Silicon is right below carbon in the periodic table of the elements, and like carbon, silicon can form polymers (long chains of molecules). You may have used silicone rubber as a glue or sealant. You can make the sodium silicate solution polymerize into long chains by adding an alcohol, such as ethanol or the isopropanol (rubbing alcohol) in your medicine cabinet. The result is polydiethyl or polydiisopropyl silicate.

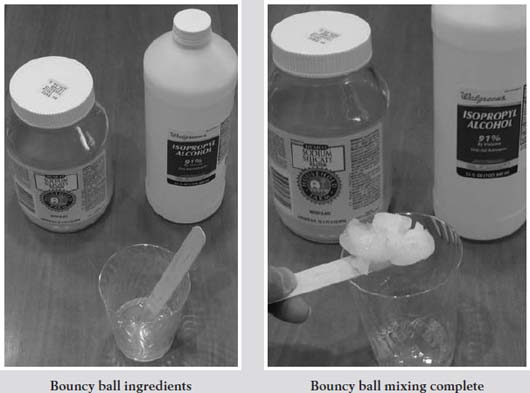

Place 2 tablespoons of sodium silicate solution into a disposable cup, and add 1 tablespoon of rubbing alcohol.

Next, stir the mixture with a craft stick or disposable plastic spoon for a few seconds to get a thick white mass of

polymerized polydiisopropyl silicate, mixed with some water and alcohol.

Now form the mass into a ball with your hands, under running warm water. The warm water helps remove the excess alcohol and form the ball more easily. It also helps wash the slimy polymer from your hands.

The result of our two-minute effort is a remarkably bouncy ball. If dropped, it recovers a large part of the height of the drop on each bounce.

It is not a paste made from teeth. Toothpaste is made from abrasives and detergents, usually with other minor ingredients to add special features.

A simple toothpaste can be made from baking soda and salt. Both of these ingredients act as abrasives to help the toothbrush scrub off the film in the mouth left by germs.

About half of a typical toothpaste is abrasives. Typical abrasives used are sodium bicarbonate (baking soda), calcium carbonate (chalk), aluminum hydroxide, hydroxyapatite, and hydrated silica (opal). Hydroxyapatite is as hard as tooth enamel, and hydrated silica is harder than tooth enamel, so both of those can wear the teeth down more than the softer abrasives listed before them.

The detergents used in toothpaste are generally the same ones used in shampoo. They help clean your teeth in the same way as shampoo cleans your hair, and they create the foam when you brush. You can't taste the detergent because toothpastes are usually very strongly flavored to overcome the taste of what the brush is removing from the teeth.

Tooth enamel can be strengthened against cavities by adding fluoride to toothpaste. Antibacterial agents are sometimes added to kill bacteria that form films of plaque. Sodium polyphosphate is added to toothpaste to reduce the formation of tartarâplaque that has become hardened by the calcium phosphate salts in saliva. Whitening toothpastes contain peroxides that bleach the teeth.

Dress shoes are still mostly made of leather. Athletic shoes these days are mostly rubber, plastic, and cloth, sometimes with a little leather.

Untreated animal skins absorb water and rot easily. To prevent this, the skins are tanned. Tanning is a process in which skins are treated with chemicals that cause the proteins to link together,

called

cross-linking.

Tanning makes the leather more waterproof, less likely to rot, and more supple.