What If? (35 page)

Authors: Randall Munroe

Lego Bridge

Q.

How many Lego bricks would it take to build a bridge capable of carrying traffic from London to New York? Have that many Lego bricks been manufactured?

—Jerry Petersen

A.

Let’s start with a

less ambitious goal.

Making the connection

Th

ere have certainly been enough Lego

1

bricks to

connect

New York and London.In LEGO

2

units, New York and London are 700 million

studs apart.

Th

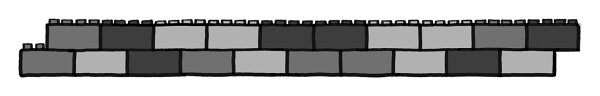

at means that if you arranged bricks like this . . .

. . . it would take 350 million of them to connect the two cities.

Th

e bridge wouldn’t be able to hold itself together or carry anything bigger than a

LEGO®

3

minifig, but it’s a start.

Th

ere have been over 400 billion Lego

4

pieces produced over the years. But how many of those are bricks that would help with a bridge, and how many are little helmet visors that get lost in the carpet?

Let’s assume we’re building our bridge out of the most common LeGo

5

piece

—

the 2x4 brick.

Using data provided by Dan Boger, Lego

6

kit archivist and operator of the

Peeron.com

Lego data site, I’ve come up with the following rough estimate: 1 out of every 50 to 100 pieces is a 2x4 rectangular brick.

Th

is suggests there are about 5–10 billion 2x4 bricks in existence, which is more than enough for our one-block-wide bridge.

Supporting cars

Of course, if we want

to support actual traffic, we’ll need to make the bridge a little wider.

We probably want to make the bridge float.

Th

e Atlantic Ocean is deep,

[

citation needed

]

and we want to avoid building 3-mile-high pylons out of Lego bricks if we can.

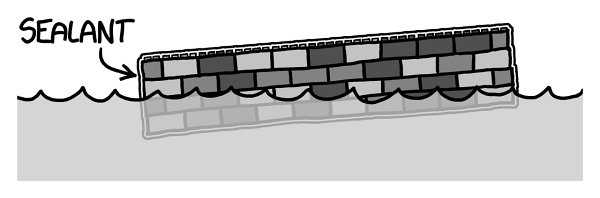

Lego bricks don’t make a watertight seal when you connect them together,

7

and the plastic used to make them is denser than water.

Th

at’s easy enough to solve; if we put a layer of sealant over the outer surface, the resulting block is substantially less dense than water.

For every cubic meter of water it displaces, the bridge can carry 400 kg. A typical passenger car weighs a little under 2000 kg, so our bridge will need a minimum of 10 cubic meters of Lego supporting each passenger car.

If we make the bridge a meter thick and 5 meters wide, then it should be able to stay afloat without any trouble

—

although it might ride low in the water

—

and

be sturdy enough to drive on.

Legos

8

are quite strong; according to a

BBC

investigation, you could stack a quarter of a million 2x2 bricks on top of each other before the bottom one collapsed.

9

Th

e first problem with this idea is that there aren’t nearly enough Lego blocks in the world to build this kind of bridge. Our second problem is the ocean.

Extreme forces

Th

e North Atlantic

is a stormy place. While our bridge would manage to avoid the fastest-moving parts of the Gulf Stream current, it would still be subjected to powerful wind and wave forces.

How strong could we make our bridge?

Th

anks to a researcher at the University of Southern Queensland named Tristan Lostroh, we have some data on the tensile strength of certain Lego joints.

Th

eir conclusion, like the

BBC

’s, is that Lego bricks are surprisingly tough.

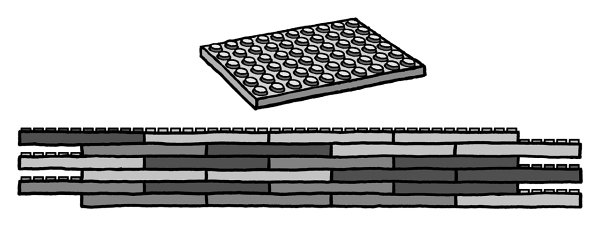

Th

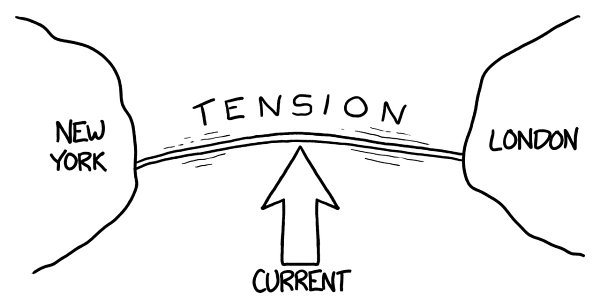

e optimal design would use long, thin plates overlapped with each other:

Th

is design would be pretty strong

—

the tensile strength would be comparable to concrete

—

but not nearly strong enough.

Th

e wind, waves, and current would push the center of the bridge sideways, creating tremendous tension in the bridge.

Th

e traditional way to deal with this situation would be to anchor the bridge to the ground so it can’t drift too far to one side. If we allow ourselves to use cables in addition to the Lego bricks,

10

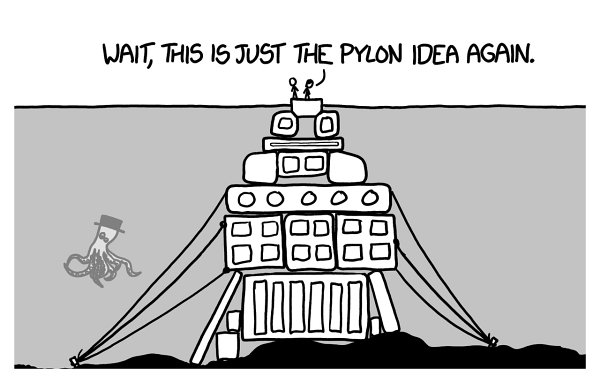

we could conceivably tether this massive contraption to the sea floor.

11

But the problems don’t end there. A 5-meter bridge might be able to support a vehicle on a placid pond, but our bridge needs to be large enough to stay above water when waves are breaking over it. Typical wave heights on the open ocean could be several meters, so we need the deck of our bridge to be floating at least, say, 4 meters above the water.

We can make our structure

more buoyant by adding air sacs and hollows, but we also need to make it wider

—

otherwise it will tip over.

Th

is means we have to add more anchors, with floats on those anchors to keep them from sinking.

Th

e floats create more drag, which puts more stress on the cables and pushes our structure downward, requiring more floats on the structure . . .

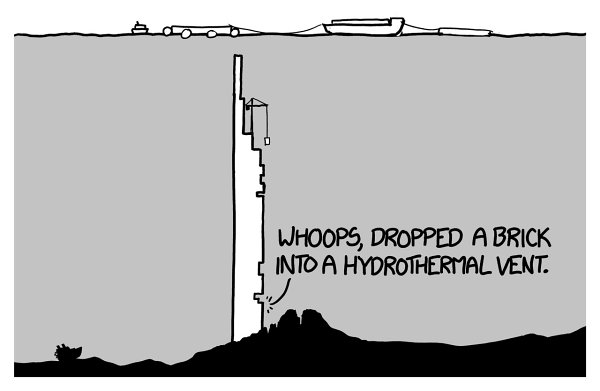

Sea floor

If we want to build our bridge down to the sea floor, we’ll have a few problems. We wouldn’t be able to keep the air sacs open under the pressure, so the structure would have to support its own weight. To handle the pressure from the ocean currents, we’d have to make it wider. In the end, we’d effectively be building a causeway.

As a side effect, our bridge would

halt the North Atlantic Ocean circulation. According to climate scientists, this is “probably bad.”

12

Furthermore, the bridge would cross the mid-Atlantic ridge.

Th

e Atlantic sea floor is spreading outward from a seam down the middle, at a rate

—

in Lego units

—

of one stud every 112 days. We would have to build in expansion joints, or drive out to the middle every so often and add a bunch of

bricks.